Incinerator History of Pacific Steel Casting

|

Shut Down Incinerator

L A Wood, Berkeley Voice, June 10, 1999

Marc Albert's story on Pacific Steel Casting Company should be corrected to read that an incinerator was installed in 1998, and not 1989, at the West Berkeley site. Many of those living under the cloud of PSC stacks are quite surprised to read about the new incinerator since a Bay Area Air Quality Management Board's "Unconditional Order of Abatement" has been in force to reduce emissions and public nuisance since the mid 1980s. Yet, last year, with the installation of the incinerator, PSC's sitewide emissions rose substantially.In fact, particulates increased 70 percent, nitrous oxides 35 percent, and carbon monoxide over 80 percent, along with increases in formaldehyde, phenols, metals and organic compounds, when compared to the last annual air-emissions report in 1997. The answer to the argument over whether the new equipment is an incinerator or a bake oven is simple. Bake ovens generally operate at 400 degrees - 500 degrees F, where as incinerators, typically burn at much higher temperatures, like the one at PSC which burns at 1400 F.

The emissions from their respective stacks is also quite different. Bake ovens produce large amounts of organics. This is reflected in the other bake ovens on site for mold and casing manufacturing. PSC's sitewide emissions for organics are over 37 tons annually. PSC's incinerator is supposed to produce less than 90 pounds of organics, but will also generate increased amounts of other chemicals while processing 10,000 tons of sand annually. It's doubtful that this new incinerator would have been allowed to operate if the community had been properly notified about the project.

This incinerator was virtually hidden from the public even though it was officially endorsed by Berkeley's mayor and the Economic Development Office. It even won a state business award. Now the incinerator project is being offered as a model for other Bay Area urban foundries.It's no wonder that so few are willing to look at this pilot project critically, or to question its sustainability in any urban environment.

The questions raised in public discussions during the early 1980s resulted in some changes at PSC as they began to address the nuisance odors from the site. However, the discussions about health impacts were simply deferred, and to date, no complete health assessment has ever been completed. This is the unanswered question of the abatement order, and is again raised by the public's discovery of the new incinerator. What is the potential for causing serious illness to those living and working around PSC from low-level and long-term exposure?

Despite two decades of community focus, we unfortunately don't know much more about the atmosphere chemistry and dispersion, the exposure pathways, the chemical compositions, or the chemical byproducts associated with PSC's emissions. Back in 1982, the medical and chemical issues were tabled for lack of scientific understanding. Today, we better understand the carcinogenic aspects of PSC's emissions and how low-level exposure affects health and human development. It's about more than unpleasant odors; it's about the chemicals we don't smell and their effects on human health! This is the missing piece in this failed regulatory process.

Frankly, there has never been a real commitment to the understanding of the health impacts of air emissions by PSC, or by BAAQMD. Yet $1 million was invested to install an incinerator, some of which was public money. BAAQMD, which originally stood with the Berkeley and Albany communities in addressing this issue, now chooses to hide behind PSC and some local officials. Moreover, a decade has passed since the Department of Health Services first suggested that a study and health assessment of PSC's emissions be undertaken. Where is their completed health assessment, one which factors in the incinerator emissions? And where is DHS now the PSC is requesting relief from BAAQMD's abatement order?

A health risk assessment must be conducted which directly addresses long-term, low-level exposures, and its effects on residents surrounding the facility. Let's begin with an ambient air station placed in the childcare facility next to PSC and not for just one day, but long-term monitoring, so we can begin to really know the air quality impacts and human health risks from this foundry. This is the least that is owed to our community.

Finally, the waste incinerator at PSC is much like the old trash burners found in most residential backyards of the 1950s. We stopped burning our residential trash long ago. Now, we must ask why the city of Berkeley allows BAAQMD, or more specifically, PSC, to burn its trash in the backyards of West Berkeley and Albany. Shut down the incinerator now!

CALCIFIRE® Sand Reclamation Technology

Pacific Steel Casting System

RMDZ News 1996/97

RMDZ Loan Helps Solve Berkeley Disposal DilemmaOne of Berkeley’s largest employers Pacific Steel Casting, Inc. will be able to expand operations and annually reuse some 8,000 tons of casting sand a year that for decades has been thrown away. The reuse of this sand is possible thanks to a $684,950 loan presented to the company by the Waste Board. The loan for $648,950 was funded in the first quarter of 1997. The proceeds of the loan were employed in the purchase of a Fluid Bed Calcifire Thermal Sand Reclamation System which will allow Pacific Steel to clean and reconstitute casting sand for reuse on site.

The granting of this loan will help the company in the diversion 8,000 tons of casting sand from the Richmond Landfill, and will employ 4 additional people. Pacific Steel generates nearly 6 percent of Berkeley’s solid waste. By keeping 8,000 tons of sand out of area landfills, the project will significantly help the city move toward its goal of reusing or recycling half its solid waste annually by the year 2000.

Note: Pacific Steel Casting received a California Association of Local Economic Development

Award of Excellence in 1998 for their Sand Recycling Project from the City of Berkeley. At that time there was no mention of the severe environmental impacts of this technology would have on the downwind residential communities in Northwest Berkeley (Oceanview) or that the installation was also in direct violation of the 1985 court ordered unconditional order of abatement for odor.)

**********

CALCIFIRE® Sand Reclamation Technology*

CALCIFIRE reclamation technology enables most chemically bonded sand to be efficiently reclaimed to a quality equaling or exceeding new sand quality.

CALCIFIRE systems are also available for reclaiming clay bonded sand (green sand)

The CALCIFIRE design features combustion of the binder material in a direct-fired fluid bed chamber which, unlike competitive units, introduces sand from the top and provides full fluidization wall-to-wall. Air and natural gas are introduced automatically through special distributor tubes as needed to start combustion. Gas levels are then reduced by PLC controller to the minimum amount necessary to maintain the preset bed operating temperature. Because most of the fuel for combustion is often the binder material itself and because combustion takes place directly within the fluidized sand, gas consumption and operating costs are kept low.

Additional gas or oxygen can be added when higher temperatures are desired. Heat-resistant steel and ceramic fiber insulation eliminate the need for costly ram-up type refractory linings, ceramic membranes or temperature-resistant moving mechanical parts. Without a lining to preheat, the unit can achieve working temperature in minutes, not hours. Sand flow through the fluid bed is easily regulated for desired effectiveness. Sand can be reused in molds or cores at costs competitive with new sand costs in most areas.

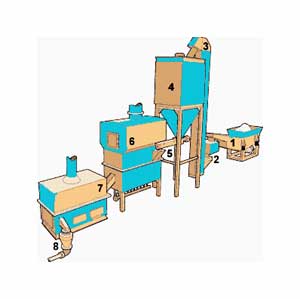

The CALCIFIRE unit is often only a part of a complete reclamation system. We regularly supply the following system components:

1. HLD Lumpreducer

2. Magnetic separator

3. Hi-temp bucket elevator

4. Pre-reclaimed sand storage hopper

5. Metering screw conveyor

6. CALCIFIRE thermal reclaimer

7. Hi-temp cooler/classifier

8. Dependaveyor pneumatic sand transporter

Dependable offers the CALCIFIRE with throughput capacities from ½ tph (.46 mtph) to 5 tph (4.5 mtph). The CALCIFIRE unit may be supplied as a stand-alone system, or as part of a larger system, integrated with other reclamation functions as required.

Dependable Foundry Equipment Company, a division of Tromley Industrial Holdings, Inc. of Tualatin, Ore. also employs a gas-fired fluidized bed in its Calcifire® sand reclamation unit. Instead of an indirect-fired heat exchanger, the Calcifire incorporates a direct firing concept in the fluidized bed. "Direct firing eliminates any problems with heat exchanger burn-out," explains Bill Zachary, senior vice-president, Dependable Foundry. "We can also reach higher temperatures.

You need 1,300 to 1,400 degrees fahrenheit to burn off the binders and achieve emissions at or below EPA standards, but the Calcifire can operate as high as 1,700 degrees."The Calcifire does not employ moving parts or ceramics; high-alloy steel in the combustion chamber reduces the maintenance normally associated with refractory material.

By using direct gas firing, the calcining process is especially effective on both green sand and chemically bonded sands. Heat-up time is short--from ambient to calcining operation levels in 60 minutes or less--and energy efficiencies are optimized by precise control of gas input to compensate for fuel content in the waste sand. Capacities range from one-half to five tons per hour.

A Calcifire unit was recently installed at Pacific Steel Foundry in Berkeley, Calif. "They love the idea that it doesn't need any attention," Zachary says. "They lock it up in a room, feed it used sand and leave it alone to do its job."

"We've found that the chemical binders in the foundry sand can provide a major source of fuel," says Brent Gudgeon, president of Gudgeon Brothers. "Using the binders as a supplemental fuel source during the treatment stage, we can get up to 18,000 btu per pound of sand, cutting the fuel consumption to a fair degree." [Note: This comment is regarding the recycler of another company, but the same thing applies to Calcifire technology.]

* source: http://www.dfrc.com/sand/sand4.php 14mar2006 & source: http://aga.activematter.com/Template.cfm?Section=Past_Issues1 &template=/ContentManagement/ContentDisplay.cfm&ContentID=1768 14mar2006

All Rights Reserved